Geothermal heat pump

From Wikipedia, the free encyclopedia

| This article needs additional citations for verification. Please help improve this article by adding reliable references (ideally, using inline citations). Unsourced material may be challenged and removed. (April 2008) |

| This article may require copy-editing for grammar, style, cohesion, tone or spelling. You can assist by editing it now. A how-to guide is available. (December 2008) |

A geothermal heat pump system is a central heating and/or air conditioning system that actively pumps heat to or from the shallow ground. It uses the earth as either a source of heat in the winter, or as a coolant in the summer. This design takes advantage of moderate temperatures in the shallow ground to boost efficiency and reduce operational costs. It may be combined with solar heating to form a geosolar system with even greater efficiency.

Geothermal heat pumps are also known by a variety of other names, including geoexchange, earth-coupled, earth energy, ground-source or water-source heat pump. The engineering and scientific community tend to prefer the terms "geoexchange" or "ground-source heat pumps" because very little of the heat originates from true geological sources.[1] Instead, these pumps draw energy from shallow ground heated by the sun in the summer. Genuine geothermal energy from the core of Earth is available only in places where volcanic activity comes close to the surface, and can usually be extracted without the help of a heat pump.

Like a refrigerator or air conditioner, these systems use a heat pump to force the transfer of heat. Heat pumps can capture heat from a cool area and transfer it to a warm area, against the natural direction of flow, or they can enhance the natural flow of heat from a warm area to a cool one. The core of the heat pump is a loop of refrigerant pumped through a vapor-compression refrigeration cycle that moves heat. Heat pumps are always more efficient than pure electric heating, even when extracting heat from air.

But unlike an air-source heat pump, which extracts or exhausts heat to or from the outside air, a ground-source heat pump exchanges heat with the ground. This is much more efficient because underground temperatures are relatively stable through the year. Seasonal variations drop off with depth and disappear below 10 m due to thermal inertia.[2] Like a cave, the shallow ground temperature is warmer than the air above during the winter and cooler than the air in the summer. A ground-source heat pump extracts that ground heat in the winter (heating) and exhausts heat back into the ground in the summer (cooling).

The system cost is much higher than conventional systems, but the difference is usually returned in energy savings in 3–10 years. System life is estimated at 25 years for the inside components and 50+ years for the ground loop.[3] As of 2004, there are over a million units installed worldwide providing 12 GW of thermal capacity, with an annual growth rate of 10%.[4] If deployed on a large scale, this technology may help alleviate energy costs and global warming.

Contents |

[edit] Ground heat exchanger

Heat pumps provide wintertime heating by extracting heat from a source and exhausting it to the building. In theory, heat can be extracted from any source, no matter how cold, but a warmer source allows higher efficiency. A ground-source heat pump uses the shallow ground as a source of heat, thus taking advantage of its seasonally moderate temperatures.

In the summer, the process can be reversed so the heat pump extracts heat from the building and exhausts it to the ground. Exhausting heat to a cooler sink is more efficient, so the air-conditioning efficiency of the heat pump again benefits from the moderate ground temperatures.

Ground-source heat pumps must have a heat exchanger in contact with the ground or groundwater to extract or exhaust heat. Several major design options are available for these.

[edit] Direct exchange

Direct exchange geothermal heat pumps are the oldest and conceptually easiest geothermal system to understand. Unlike most installed systems, which have two heat exchange loops in series on the ground side, the direct exchange system has a single-loop of refrigerant in direct thermal contact with the ground. The refrigerant leaves the heat pump appliance cabinet, circulates through a loop of copper tube buried underground, and exchanges heat with the ground before returning to the pump. The name "direct exchange" refers to heat transfer between the refrigerant and the ground without the use of an intermediate fluid. There is no direct interaction between the fluid and the earth; only heat transfer across the pipe.

Direct exchange systems are 20-25% more efficient and have potentially lower installation costs than water systems. While they require much more refrigerant and their tubing is more expensive per foot, they require 1/3 to 1/2 the length of tubing, half the diameter of drilled holes, and therefore lower drilling or excavation costs. Higher joint quality is needed in the tubing to prevent the refrigerant gas from leaking. The copper loop must be protected from corrosion in acidic soil through the use of a sacrificial anode. Direct exchange heat pumps are usually excluded by the terms "water-source heat pumps" or "water loop heat pumps" since there is no water in the ground loop.

[edit] Closed loop

Most ground-source heat pump system have two loops on the ground side: the primary refrigerant loop is contained in the appliance cabinet where it exchanges heat with a secondary water loop that is buried underground. In a closed loop system, the secondary loop is typically made of High-density polyethylene pipe and contains a mixture of water and anti-freeze (propylene glycol, denatured alcohol or methanol). After leaving the internal heat exchanger, the water flows through the secondary loop outside the building to exchange heat with the ground before returning. The secondary loop is placed below the frost line where the temperature is more stable, or preferably submerged in a body of water if available. Systems in wet ground or in water are generally more efficient than dryer ground loops since it is less work to move heat in and out of water than solids in sand or soil.

As compared to direct exchange systems, closed loop systems need an additional heat exchanger between the refrigerant loop and the water loop, as well as an extra water pump. Some manufacturers have a separate ground loop fluid pump pack, while some integrate the pumping and valving within the heat pump. Expansion tanks and pressure relief valves may be installed on the heated fluid side. The lower efficiency of closed loop systems requires longer and larger pipe to be placed in the ground, increasing excavation costs. ASHRAE defines the term ground-coupled heat pump to encompass closed loop and direct exchange systems, while excluding open loops.

Closed loop tubing can be installed horizontally as a loop field in trenches or vertically as a series of long U-shapes in wells(see below). The size of the loop field depends on the soil type and moisture content, the average ground temperature and the heat loss and or gain characteristics of the building being conditioned. A rough approximation of the initial soil temperature is the average daily temperature for the region.

[edit] Vertical

A vertical closed loop field is composed of pipes that run vertically in the ground. A hole is bored in the ground, typically, 75 to 500 plus feet deep. Pipe pairs in the hole are joined with a U-shaped cross connector at the bottom of the hole. The borehole is commonly filled with a bentonite grout surrounding the pipe to provide a good thermal connection to the surrounding soil or rock to maximize the heat transfer. Grout also protects the ground water from contamination, and prevents artesian wells from flooding the property. Vertical loop fields are typically used when there is a limited area of land available. Bore holes are spaced 5–6 m apart and the depth depends on ground and building characteristics. For illustration, a detached house needing 10kW (3 ton) of heating capacity might need 3 boreholes 80 to 110 m (270 to 350 feet) deep.[5] (A ton of heat is 12,000 British thermal units per hour (BTU/h) or 3.5 kilowatts.) During the cooling season, the local temperature rise in the bore field is influenced most by the moisture travel in the soil. Reliable heat transfer models have been developed through sample bore holes as well as other tests.

[edit] Horizontal

A horizontal closed loop field is composed of pipes that run horizontally in the ground. A long horizontal trench, deeper than the frost line, is dug and U-shaped or slinky coils are placed horizontally inside the same trench. Horizontal loop fields are very common and economical if there is adequate land available. For illustration, a detached house needing 10kW (3 ton) of heating capacity might need 3 loops 120 to 180 m (400 to 600 feet) long of 3/4 inch (19mm) or 1.25 inch inside diameter polyethylene tubing at a depth of 1 to 2 m (3 to 6 feet).[5]

A slinky (also called coiled) closed loop field is a type of horizontal closed loop where the pipes overlay each other. The easiest way of picturing a slinky field is to imagine holding a slinky on the top and bottom with your hands and then move your hands in opposite directions. A slinky loop field is used if there is not adequate room for a true horizontal system, but it still allows for an easy installation. Rather than using straight pipe, slinky coils, use overlapped loops of piping laid out horizontally along the bottom of a wide trench. Depending on soil, climate and your heat pumps’ run fraction, slinky coil trenches can be anywhere from one third to two thirds shorter than traditional horizontal loop trenches. Slinky coil ground loops are essentially a more economic and space efficient version of a horizontal ground loop [6].

[edit] Pond

A closed pond loop is not common because it depends on proximity to a body of water, where an open loop system is usually preferable. A pond loop may be advantageous where poor water quality precludes an open loop, or where the system heat load is small. A pond loop consists of coils of pipe - similar to a slinky loop - attached to a frame and located at the bottom of an appropriately sized pond or water source.

[edit] Open loop

In an open loop system, (also called a groundwater heat pump,) the secondary loop pumps natural water from a well or body of water into a heat exchanger inside the heat pump. ASHRAE calls open loop systems groundwater heat pumps or surface water heat pumps, depending on the source. Heat is either extracted or added by the primary refrigerant loop, and the water is returned to a separate injection well, irrigation trench, or body of water. The supply and return lines must be placed far enough apart to ensure thermal recharge of the source. Since the water chemistry is not controlled, the appliance must be protected from corrosion by using different metals in the heat exchanger and pump. Limescale may foul the system over time and require periodic acid cleaning. If the water contains high levels of salt, minerals or hydrogen sulfide, a closed loop system is usually preferable.

Deep lake water cooling uses a similar process with an open loop for air conditioning and cooling. Open loop systems using ground water are usually more efficient than closed systems because they are better coupled with ground temperatures. Closed loop systems, in comparison, have to transfer heat across extra layers of pipe wall and dirt.

Some types of open-loop systems are illegal in Ontario, after the Walkerton Tragedy, and other jurisdictions may not allow some of these systems which may drain aquifers or possibly contaminate wells.

[edit] Standing column well

A standing column well system is a specialized type of open loop system. Water is drawn from the bottom of a deep rock well, passed through a heat pump, and returned to the top of the well, where traveling downwards it exchanges heat with the surrounding bedrock.[7] The choice of a standing column well system is often dictated where there is near-surface bedrock and limited surface area is available. A standing column is typically not suitable in locations where the geology is comprised of mostly clay, silt, or sand. If bedrock is deeper than 200 feet (61 m) from the surface, the cost of casing to seal off the overburden may become prohibitive.

A multiple standing column well system can support a large structure in an urban or rural application. The standing column well method is also popular in residential and small commercial applications. There are many successful applications of varying sizes and well quantities in the many boroughs of New York City, and is also the most common application in the New England states. This type of ground source system has some heat storage benefits, where heat is rejected from the building and the temperature of the well is raised, within reason, during the Summer cooling months which can then be harvested for heating in the Winter months, thereby increasing the efficiency of the heat pump system. As with closed loop systems, sizing of the standing column system is critical in reference to the heat loss and gain of the existing building. As the heat exchange is actually with the bedrock, using water as the transfer medium, a large amount of production capacity (water flow from the well) is not required for a standing column system to work. However, if there is adequate water production, then the thermal capacity of the well system can be enhanced by periodic discharge during the peak Summer and Winter months.

Since this is essentially a water pumping system, standing column well design requires critical considerations to obtain peak operating efficiency. Should a standing column well design be misapplied, leaving out critical shut-off valves for example, the result could be an extreme loss in efficiency and thereby cause operational cost to be higher than anticipated.

[edit] Building distribution

The heat pump is the central unit that becomes the heating and cooling plant for the building. Some models may cover space heating, space cooling, (space heating via conditioned air, hydronic systems and / or radiant heating systems), domestic or pool water preheat (via the desuperheater function, demand hot water, and driveway ice melting all within one appliance with a variety of options with respect to controls, staging and zone control. The heat may be carried to its end use by circulating water or forced air. Almost all types of heat pumps are produced for commercial and residential applications.

Liquid-to-air heat pumps (also called water-to-air) output forced air, and are most commonly used to replace legacy forced air furnaces and central air conditioning systems. There are variations that allow for split systems, high-velocity systems, and ductless systems. Heat pumps cannot achieve as high of a fluid temperature as a conventional furnace, so they require a higher volume flow rate of air to compensate. When retrofitting a residence, the existing duct work may have to be enlarged to distribute the heat throughout the house.

Liquid-to-water heat pumps (also called water-to-water) are hydronic systems that use water to carry heating or cooling through the building. Systems such as radiant underfloor heating, baseboard radiators, conventional cast iron radiators would use a liquid-to-water heat pump. These heat pumps are preferred for pool heating or domestic hot water pre-heat. Heat pumps can only heat water to ~50°C (120°F) efficiently, whereas a boiler normally reaches 65-95°C. (150-200°F) Legacy radiators designed for these higher temperatures may have to be doubled in numbers when retrofitting a home. A hot water tank will still be needed to raise water temperatures above the heat pump's maximum, but pre-heating will save 25-50% of hot water costs.

Ground-source heat pumps are especially well matched to underfloor heating and baseboard radiator systems which only require warm temperatures (40°C) to work well. Thus they are ideal for open plan offices. Using large surfaces such as floors, as opposed to radiators, distributes the heat more uniformly and allows for a lower water temperature. Wood or carpet floor coverings dampen this effect because the thermal transfer efficiency of these materials is lower than that of masonry floors (tile, concrete). Underfloor heating cannot be used for cooling because atmospheric humidity would condense on the floor.

Combination heat pumps are available that can produce forced air and circulating water simultaneously and individually. These systems are largely being used for houses that have a combination of air and liquid conditioning needs, for example central air conditioning and pool heating.

[edit] Seasonal thermal storage

The efficiency of ground-source heat pumps can be improved by using seasonal thermal storage. If heat loss from the ground source is sufficiently low, the heat pumped out of the building in the summer can be retrieved in the winter. Heat storage efficiency increases with scale, so this advantage usually only applies to commercial or district heating systems. Geosolar combisystems further augment this efficiency by collecting extra solar energy during the summer (more than is needed for air conditioning) and concentrating it in the store.

Such a system has been used to heat and cool a greenhouse using an aquifer for thermal storage.[8] In summer, the greenhouse is cooled with cold ground water. This heats the water in the aquifer which can become a warm source for heating in winter. [8][9]. The combination of cold and heat storage with heat pumps can be combined with water/humidity regulation. These principles are used to provide renewable heat and renewable cooling to all kinds of buildings.

[edit] History

The heat pump was imagined by Lord Kelvin in 1852 and developed by Peter Ritter von Rittinger in 1855. After experimenting with a freezer, Robert C. Webber built the first direct exchange ground-source heat pump in the late 1940s. [10] The first successful commercial project was installed in the Commonwealth Building (Portland, Oregon) in 1946, and has been designated a National Historic Mechanical Engineering Landmark by ASME.[11] The technology became popular in Sweden in the 1970's, and has been growing slowly in worldwide acceptance since then. Open loop systems dominated the market until the development of polybutylene pipe in 1979 made closed loop systems economically viable.[11] As of 2004, there are over a million units installed worldwide providing 12 GW of thermal capacity.[4] Each year, about 80,000 units are installed in the USA and 27,000 in Sweden.[4]

[edit] Thermal efficiency

The net thermal efficiency of a heat pump should take into account the efficiency of electricity generation and transmission, typically about 40%.[4] Since a heat pump takes heat from the ground, the total heat energy output to the building is greater than the electricity input. This results in thermal efficiencies greater than 100%, up to around 150%.

Net thermal efficiency tends to be confusing to consumers, so heat pump performance is generally expressed as the ratio of heat output to electricity input. An allowance is included for electricity used by the fluid pumps. Cooling performance is typically expressed in units of BTU/hr/Watt as the Energy Efficiency Ratio, (EER) while heating performance is typically reduced to dimensionless units as the Coefficient of Performance. (COP) The conversion factor is 3.41 BTU/hr/Watt. Both of these measures will vary depending on the temperature difference between the ground source and the building, which can vary greatly between installations and over the course of the year.

For the sake of comparing ground source heat pump appliances to each other, independent of installation variations, a few standard test conditions have been established by the American Refrigerant Institute (ARI) and the International Standards Organization. Standard ARI 330 ratings are intended for closed loop ground-source heat pumps, and assumes secondary loop water temperatures of 77°F for air conditioning and 32°F for heating. These temperatures are typical of installations in the northern USA. Standard ARI 325 ratings are intended for open loop ground-source heat pumps, and include two sets of ratings for groundwater temperatures of 50°F and 70°F. ARI 325 budgets more electricity for water pumping than ARI 330. Neither of these standards attempt to account for seasonal variations. Standard ARI 870 ratings are intended for direct exchange ground-source heat pumps. ISO 13256-1 ratings are intended for open loop and closed loop systems.

Residential ground source heat pumps on the market today have COP's ranging from 2.4 to 3.8 and EER's ranging from 10.6 to 17.5.[1] To qualify for an Energy Star label, heat pumps must meet certain minimum COP and EER ratings which depend on the ground heat exchanger type. For closed loop systems, the ISO 13256-1 heating COP must be 3.3 or greater and the cooling EER must be 14.1 or greater. [12]

Undisturbed earth below the frost line remains at a relatively constant temperature year round. This temperature equates roughly to the average annual air-temperature of the chosen location. It is usually 7-12°C (45-54°F) at a depth of six meters in locations where heating is needed in winter. Ground-source heat pumps rely on this near constant temperature as a base temperature that is raised or lowered minimally to create a desirable indoor temperature. Because this temperature remains more constant than the air temperature throughout the seasons, geothermal heat pumps perform with far greater efficiency and are stressed less during extreme air temperatures than fueled or electric conventional air conditioners and furnaces. A particular advantage is that they can use electricity to heat spaces and water much more efficiently than an electric heater.

Seasonal variations are much more important for air-source heat pumps, and ARI 210 and 240 define Seasonal Energy Efficiency Ratios (SEER) and Heating Seasonal Performance Factors (HSPF) to take into seasonal variations into account for these units. These numbers are normally not applicable and should not be compared to ground-source heat pump ratings. However, Natural Resources Canada has adapted this approach to calculate typical seasonally adjusted HSPF's for ground-source heat pumps in Canada.[5] The NRC HSPF's ranged from 8.7 to 12.8 BTU/hr/Watt (2.6 to 3.8 in nondimensional factors, or 255% to 375% seasonal average electricity utilization efficiency) for the most populated regions of Canada. When combined with the thermal efficiency of electricity, this corresponds to net average thermal efficiencies of 100% to 150%.

[edit] Environmental impact

The U.S. Environmental Protection Agency (EPA) has called ground-source heat pumps the most energy-efficient, environmentally clean, and cost-effective space conditioning systems available.[13] Heat pumps offer significant emission reductions potential, particularly where they are used for both heating and cooling and where the electricity is produced from renewable resources.

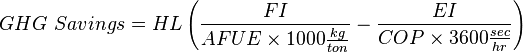

Ground-source heat pumps have unsurpassed thermal efficiencies and produce zero emissions locally, but their electricity supply almost always includes components with high greenhouse gas emissions. Their environmental impact therfore depends on the characteristics of the electricity supply. The GHG emissions savings from a heat pump over a conventional furnace can be calculated based on the following formula:[2]

| Country | Electricity CO2 Emissions Intensity |

GHG savings relative to | ||

|---|---|---|---|---|

| natural gas | heating oil | electric heating | ||

| Canada | 223 ton/GWh[14][15][16] | 2.7 ton/yr | 5.3 ton/yr | 3.4 ton/yr |

| Russia | 351 ton/GWh[14][15] | 1.8 ton/yr | 4.4 ton/yr | 5.4 ton/yr |

| USA | 676 ton/GWh [15] | -0.5 ton/yr | 2.2 ton/yr | 10.3 ton/yr |

| China | 839 ton/GWh[14][15] | -1.6 ton/yr | 1.0 ton/yr | 12.8 ton/yr |

- HL = seasonal heat load ≈ 80 GJ/yr for a modern detached house in the northern USA

- FI = emissions intensity of fuel = 50 kg(CO2)/GJ for natural gas, 73 for heating oil

- AFUE = furnace efficiency ≈ 95% for a modern condensing furnace

- COP = heat pump efficiency factor ≈ 3.2 seasonally adjusted for northern USA heat pump

- EI = emissions intensity of electricity ≈ 200-800 ton(CO2)/GWh, depending on region

Ground-source heat pumps always produce less greenhouse gases than air conditioners, oil furnaces, and electric heating, but natural gas furnaces may be competitive depending on the greenhouse gas intensity of the local electricity supply. In countries like Canada and Russia with low emitting electricity infrastructure, a residential heat pump may save 5 tons of carbon dioxide per year relative to an oil furnace, or about as much taking an average passenger car off the road. But in countries like China or USA that are highly reliant on coal for electricity production, a heat pump may result in 1 or 2 tons more carbon dioxide emissions than a natural gas furnace.

The fluids used in closed loops may be designed to be biodegradable and non-toxic, but the refrigerant used in the heat pump cabinet and in direct exchange loops is almost unversally chlorodifluoromethane, which is an ozone depleting substance. [1] Although harmless while contained, leaks and improper end-of-life disposal contribute to enlarging the ozone hole.

Open loop systems that draw water from a well and drain to the surface may contribute to aquifer depletion, water shortages, and subsidence of the soil. There are also some concerns about groundwater contamination.

Ground-source heat pump technology, like building orientation, is a natural building technique (bioclimatic building).

[edit] Economics

Ground-source heat pumps are characterised by high capital costs and low operational costs compared to other HVAC systems. Their overall economic benefit depends primarily on the relative costs of electricity and fuels, which are highly variable over time and across the world. Based on recent prices, ground-source heat pumps currently have lower operational costs than any other conventional heating source almost everywhere in the world. Natural gas is the only fuel with competitive operational costs, and only in a handful of countries where it is exceptionally cheap, or where electricity is exceptionally expensive.[2] In general, a homeowner may save anywhere from 20% to 60% annually on utilities by switching from an ordinary system to a ground-source system.[17][18]

Captical costs and system lifespan have received much less study, and the return on investment is highly variable. One study found the total installed cost for a system with 10kW (3 ton) thermal capacity for a detached rural residence in the USA averaged $8000–$9000 in 1995 US dollars.[19] A more recent study found an average cost of $14,000 in 2008 US dollars for the same size system in Indiana.[20] Prices over $20,000 are quoted in Canada.[21] The rapid escalation in system price has been accompanied by rapid improvements in efficiency and reliability. Capital costs are known to benefit from economies of scale, particularly for open loop systems, so they are more cost-effective for larger commercial buildings and harsher climates. The initial cost can be two to five times that of a conventional heating system in most residential applications, new construction or existing. In retrofits, the cost of installation is affected by the size of living area, the home's age, insulation characteristics, the geology of the area, and location of the home/property. Proper duct system design and mechanical air exchange should be considered in the initial system cost.

| Country | Payback period for replacing | ||

|---|---|---|---|

| natural gas | heating oil | electric heating | |

| Canada | 13 years | 3 years | 6 years |

| USA | 12 years | 5 years | 4 years |

| Germany | net loss | 8 years | 2 years |

| Notes: Highly variable with energy prices Government subsidies not included Climate differences not evaluated |

|||

Capital costs may be offset by substantial subsidies from many governments, for example totalling over $7000 in Ontario for residential systems installed in the 2009 fiscal year. Some electric companies will offer special rates to customers who install a ground-source heat pump for heating/cooling their building.[22] This is due to the fact that electrical plants have the largest loads during summer months and much of their capacity sits idle during winter months. This allows the electric company to use more of their facility during the winter months and sell more electricity. It also allows them to reduce peak usage during the summer (due to the increased efficiency of heat pumps), thereby avoiding costly construction of new power plants. For the same reasons, other utility companies have started to pay for the installation of ground-source heat pumps at customer residences. They lease the systems to their customers for a monthly fee, at a net overall savings to the customer.

The life span of the system is longer than conventional heating and cooling systems. Good data on system lifespan is not yet available because the technology is too recent, but many early systems are still operational today after 25–30 years with routine maintenance. Most loop fields are warrantied for 25 to 50 years and are expected to last at least 50 to 200 years.[17][23] Ground-source heat pumps use electricity for heating the house. The higher investment above conventional oil or electric systems may be returned in energy savings in 2–10 years for residential systems in the USA.[24][23][18] If compared to compared to natural gas systems, the payback period can be much longer. The payback period for larger commercial systems in the USA is 1-5 years, even when compared to natural gas.[18]

Ground-source heat pumps are recognized as one of the most efficient heating and cooling systems on the market. They are often the second-most cost effective solution in extreme climates, (after co-generation,) despite reductions in thermal efficiency due to ground temperature. (The ground source is warmer in climates that need strong air conditioning, and cooler in climates that need strong heating.)

Commercial systems maintenance costs in the USA have historically been between $0.11 to $0.22 per m2 per year in 1996 dollars, much less than the average $0.54 per m2 per year for conventional HVAC systems. [11]

Governments that promote renewable energy will likely offer incentives for the consumer (residential), or industrial markets. For example, in the United States, incentives are offered both on the State and Federal levels of government.[25]

[edit] Installation

Because of the technical knowledge and equipment needed to properly install the piping, a GHP system installation is not a do-it-yourself project. The Geothermal Heat Pump Consortium and the Canadian GeoExchange Coalition maintain listings of qualified installers in the USA and Canada.[26].

Here is a detailed account of the installation and operation of our residential geoexchange system: http://thegeoexchange.org/

[edit] References

- ^ a b c Rafferty, Kevin (April 1997), "An Information Survival Kit for the Prospective Residential Geothermal Heat Pump Owner", Geo-Heat Centre Quarterly Bulletin (Klmath Falls, Oregon: Oregon Institute of Technology) 18 (2): pp 1-11, ISSN 0276-1084, http://geoheat.oit.edu/bulletin/bull18-2/art1.pdf, retrieved on 2009-03-21

- ^ a b c Dowlatabadi, H (9 November 2007), "Strategic GHG reduction through the use of ground source heat pump technology", Environmental Research Letters (UK: IOP Publishing) 2: 044001 8pp, doi:, ISSN 1748-9326, http://www.iop.org/EJ/article/1748-9326/2/4/044001/erl7_4_044001.pdf?request-id=dd247af1-1eb0-4c8d-a20b-426d37d8ee5f, retrieved on 2009-03-22

- ^ http://apps1.eere.energy.gov/consumer/your_home/space_heating_cooling/index.cfm/mytopic=12640

- ^ a b c d Lund, J.; Sanner, B.; Rybach, L.; Curtis, R.; Hellström, G. (September 2004), "Geothermal (Ground Source) Heat Pumps, A World Overview", Geo-Heat Centre Quarterly Bulletin (Klmath Falls, Oregon: Oregon Institute of Technology) 25 (3): pp. 1-10, ISSN 0276-1084, http://geoheat.oit.edu/bulletin/bull25-3/art1.pdf, retrieved on 2009-03-21

- ^ a b c "Ground Source Heat Pumps (Earth Energy Systems)". Heating and Cooling with a Heat Pump. Natural Resources Canada, Office of Energy Efficiency. http://oee.nrcan.gc.ca/publications/infosource/pub/home/heating-heat-pump/gsheatpumps.cfm. Retrieved on 2009-03-24. Note: contrary to air-source conventions, the NRC's HSPF numbers are in units of BTU/hr/Watt. Divide these numbers by 3.41 BTU/hr/Watt to arrive at non-dimensional units comparable to ground-source COP's and air-source HSPF.

- ^ http://www.informedbuilding.com/Geothermal/Main16/Types-of-Geothermal-Ground-Loops/

- ^ Orio, Carl D.; Johnson, Carl N.; Rees, Simon J.; Chiasson, A.; Deng, Zheng; Spitler, Jeffrey D. (2004), "A Survey of Standing Column Well Installations in North America", ASHRAE Transactions (ASHRAE) 11 (4): 637-655, http://www.hvac.okstate.edu/research/Documents/Orio_Johnson_Rees_Chiasson_Deng_Spitler_05.pdf, retrieved on 2009-03-25

- ^ a b Van Passel, Willy; Sourbron, Maarten; Verplaetsen, Filip; Leroy, Luc; Somers, Yvan; Verheyden, Johan; Coupé, Koen. Organisatie voor Duurzame Energie Vlaanderen. ed (pdf). Warmtepompen voor woningverwarming. p. 28. http://www2.vlaanderen.be/economie/energiesparen/doc/brochure_warmtepomp.pdf. Retrieved on 2009-03-23.

- ^ Schematic of similar system of aquifers with fans-regulation

- ^ "History". About Us. International Ground Source Heat Pump Association. http://www.igshpa.okstate.edu/about/about_us.htm. Retrieved on 2009-03-24.

- ^ a b c Bloomquist, R. Gordon (December 1999), "Geothermal Heat Pumps, Four Plus Decades of Experience", Geo-Heat Centre Quarterly Bulletin (Klmath Falls, Oregon: Oregon Institute of Technology) 20 (4): pp 13-18, ISSN 0276-1084, http://geoheat.oit.edu/bulletin/bull20-4/art3.pdf, retrieved on 2009-03-21

- ^ "Energy Star Program Requirements for Geothermal Heat PUmps". Partner Commitments. Energy Star. http://www.energystar.gov/ia/partners/product_specs/eligibility/geo_heat_pump_elig.pdf. Retrieved on 2009-03-24.

- ^ Environmental Protection Agency (1993). Space Conditioning: The Next Frontier - Report 430-R-93-004. EPA.

- ^ a b c European Environment Agency (2008), Energy and environment report 2008, EEA Report, No 6/2008, Luxemburg: Office for Official Publications of the European Communities, p. p83, doi:, ISBN 978-92-9167-980-5, ISSN 1725-9177, http://www.eea.europa.eu/publications/eea_report_2008_6, retrieved on 2009-03-22

- ^ a b c d Energy Information Administration, US Department of Energy (2007), Voluntary Reporting of Greenhouse Gases, Electricity Emission Factors, http://www.eia.doe.gov/oiaf/1605/pdf/Appendix%20F_r071023.pdf, retrieved on 2009-03-22

- ^ "annex 9". National Inventory Report 1990-2006:Greenhouse Gas Sources and Sinks in Canada. Government of Canada. May 2008. ISBN 978-1-100-11176-6. http://www.ec.gc.ca/pdb/ghg/inventory_report/2004_report/ta9_7_e.cfm.

- ^ a b "Geothermal Heat Pump Consortium, Inc.". http://geoexchange.us/. Retrieved on 2007-10-19.

- ^ a b c Lienau, Paul J.; Boyd, Tonya L.; Rogers, Robert L. (April 1995), Ground-Source Heat Pump Case Studies and Utility Programs, Klamath Falls, OR: Geo-Heat Center, Oregon Institute of Technology, http://geoheat.oit.edu/pdf/hp1.pdf, retrieved on 2009-03-26

- ^ Kavanaugh, Steve; Gilbreath, Christopher (December 1995), Joseph Kilpatrick, ed. (pdf), Cost Containment for Ground-Source Heat Pumps (final report ed.), http://geoheat.oit.edu/pdf/tp72.pdf, retrieved on 2009-03-24

- ^ Cummings, Paul (June 2008) (pdf), Indiana Residential Geothermal Heat Pump Rebate, Program Review, Indiana Office of Energy and Defense Development, http://www.in.gov/oed/files/GHPProgramreport.pdf, retrieved on 2009-03-24

- ^ [1] Example costs in Canada]

- ^ "Geothermal Heat Pumps". Capital Electric Cooperative. http://www.capitalelec.com/Energy_Efficiency/ground_source/index.html. Retrieved on 2008-10-05.

- ^ a b "Geothermal heat pumps: alternative energy heating and cooling FAQs". http://www.econar.com/faq.htm. Retrieved on 2007-10-19.

- ^ http://apps1.eere.energy.gov/consumer/your_home/space_heating_cooling/index.cfm/mytopic=12640

- ^ http://www.dsireusa.org/searchby/searchtechnology.cfm?&CurrentPageID=2&EE=1&RE=1

- ^ http://apps1.eere.energy.gov/consumer/your_home/space_heating_cooling/index.cfm/mytopic=12670

[edit] See also

|

||||||||||||||||||||

- Absorption heat pump

- Earth cooling tubes

- Microgeneration Certification Scheme

- Oregon Institute of Technology

- Polyphenylene sulfide

- Solar thermal cooling

- Thermosiphon

[edit] External links

- Geothermal Heat Pumps (EERE/USDOE).

- Geothermal Heat Pump Consortium

- Geothermal Heat Pump Consortium Forum

- Canadian Geoexchange Coalition

- International Geothermal Association (IGA)

- Geothermal Education Office (GEO)

- Ground Source Heat Pump Association - UK

- International Ground Source Heat Pump Association

- Fossil Freedom - Crash Course in geothermal heat pumps

- PATH Tech Inventory: Geothermal Heat Pumps

- Ground Source Heat Pumps - Heat Pump Federation UK

- DIY Geothermal Installation Support