Experience curve effects

From Wikipedia, the free encyclopedia

| It has been suggested that this article or section be merged with Learning curve. (Discuss) |

- Experience curve re-directs here. For its use in video games see Experience point.

Models of the learning curve effect and the closely related experience curve effect express the relationship between equations for experience and efficiency or between efficiency gains and investment in the effort. The experience of "learning curves" was first observed by the 19th Century German psychologist Hermann Ebbinghaus according to the difficulty of memorizing varying numbers of verbal stimuli, and subsequent learning about the complex processes of learning are discussed in the

.

The experienced learning rates for exploratory discovery and development processes, for individuals and organizations, is more the focus of the main Learning curve article. As individuals and/or organizations get more experienced at a task, they usually become more efficient at it, following a progression of the learning first getting easier and then harder as one approaches a limit. A "steep" learning curve, in colloquial usage, usually means experiencing a large and increasing amount of effort for a constant amount of learning, i.e. approaching a natural limit. Much the reverse is the meaning of a steep slope in a learning progress curve. A learning progress curve is steep when very little effort is required, as further discussed in the main article.

The rule used for representing the learning curve effect states that the more times a task has been performed, the less time will be required on each subsequent iteration. This relationship was probably first quantified in 1936 at Wright-Patterson Air Force Base in the United States[1], where it was determined that every time total aircraft production doubled, the required labour time decreased by 10 to 15 percent. Subsequent empirical studies from other industries have yielded different values ranging from only a couple of percent up to 30 percent, but in most cases it is a constant percentage: It did not vary at different scales of operation. Learning curve theory states that as the quantity of items produced doubles, costs decrease at a predictable rate. This predictable rate is described by Equations 1 and 2. The equations have the same equation form. The two equations differ only in the definition of the Y term, but this difference can make a significant difference in the outcome of an estimate.

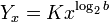

1. This equation describes the basis for what is called the unit curve. In this equation, Y represents the cost of a specified unit in a production run. For example, If a production run has generated 200 units, the total cost can be derived by taking the equation below and applying it 200 times (for units 1 to 200) and then summing the 200 values. This is cumbersome and requires the use of a computer or published tables of predetermined values.

where

is the number of direct labour hours to produce the first unit

is the number of direct labour hours to produce the first unit is the number of direct labour hours to produce the xth unit

is the number of direct labour hours to produce the xth unit is the unit number

is the unit number is the learning percentage

is the learning percentage

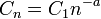

2. This equation describes the basis for the cumulative average or cum average curve. In this equation, Y represents the average cost of different quantities (X) of units. The significance of the "cum" in cum average is that the average costs are computed for X cumulative units. Therefore, the total cost for X units is the product of X times the cum average cost. For example, to compute the total costs of units 1 to 200, an analyst could compute the cumulative average cost of unit 200 and multiply this value by 200. This is a much easier calculation than in the case of the unit curve.

where

is the number of direct labour hours to produce the first unit

is the number of direct labour hours to produce the first unit is the average number of direct labour hours to produce First xth units

is the average number of direct labour hours to produce First xth units is the unit number

is the unit number is the learning percentage

is the learning percentage

Contents |

[edit] The experience curve

The experience curve effect is broader in scope than the learning curve effect encompassing far more than just labor time. It states that the more often a task is performed the lower will be the cost of doing it. The task can be the production of any good or service. Each time cumulative volume doubles, value added costs (including administration, marketing, distribution, and manufacturing) fall by a constant and predictable percentage.

In the late 1960s Bruce Henderson of the Boston Consulting Group (BCG) began to emphasize the implications of the experience curve for strategy. [3] Research by BCG in the 1970s observed experience curve effects for various industries that ranged from 10 to 25 percent.

These effects are often expressed graphically. The curve is plotted with cumulative units produced on the horizontal axis and unit cost on the vertical axis. A curve that depicts a 15% cost reduction for every doubling of output is called an “85% experience curve”, indicating that unit costs drop to 85% of their original level.

Mathematically the experience curve is described by a power law function sometimes referred to as Henderson's Law:

where

is the cost of the first unit of production

is the cost of the first unit of production is the cost of the nth unit of production

is the cost of the nth unit of production is the cumulative volume of production

is the cumulative volume of production is the elasticity of cost with regard to output

is the elasticity of cost with regard to output

[edit] Reasons for the effect

Examples

NASA quotes the following experience curves:[5]

- Aerospace 85%

- Shipbuilding 80-85%

- Complex machine tools for new models 75-85%

- Repetitive electronics manufacturing 90-95%

- Repetitive machining or punch-press operations 90-95%

- Repetitive electrical operations 75-85%

- Repetitive welding operations 90%

- Raw materials 93-96%

- Purchased Parts 85-88%

The primary reason for why experience and learning curve effects apply, of course, is the complex processes of learning involved. As discussed in the main article, learning generally begins with making successively larger finds and then successively smaller ones. The equations for these effects come from the usefulness of mathematical models for certain somewhat predictable aspects of those generally non-deterministic processes. They include:

- Labour efficiency - Workers become physically more dexterous. They become mentally more confident and spend less time hesitating, learning, experimenting, or making mistakes. Over time they learn short-cuts and improvements. This applies to all employees and managers, not just those directly involved in production.

- Standardization, specialization, and methods improvements - As processes, parts, and products become more standardized, efficiency tends to increase. When employees specialize in a limited set of tasks, they gain more experience with these tasks and operate at a faster rate.

- Technology-Driven Learning - Automated production technology and information technology can introduce efficiencies as they are implemented and people learn how to use them efficiently and effectively.

- Better use of equipment - as total production has increased, manufacturing equipment will have been more fully exploited, lowering fully accounted unit costs. In addition, purchase of more productive equipment can be justifiable.

- Changes in the resource mix - As a company acquires experience, it can alter its mix of inputs and thereby become more efficient.

- Product redesign - As the manufacturers and consumers have more experience with the product, they can usually find improvements. This filters through to the manufacturing process. A good example of this is Cadillac's testing of various "bells and whistles" specialty accessories. The ones that did not break became mass produced in other General Motors products; the ones that didn't stand the test of user "beatings" were discontinued, saving the car company money. As General Motors produced more cars, they learned how to best produce products that work for the least money.

- Value chain effects - Experience curve effects are not limited to the company. Suppliers and distributors will also ride down the learning curve, making the whole value chain more efficient.

- Network-building and use-cost reductions - As a product enters more widespread use, the consumer uses it more efficiently because they're familiar with it. One fax machine in the world can do nothing, but if everyone has one, they build an increasingly efficient network of communications. Another example is email accounts; the more there are, the more efficient the network is, the lower everyone's cost per utility of using it.

- Shared experience effects - Experience curve effects are reinforced when two or more products share a common activity or resource. Any efficiency learned from one product can be applied to the other products.

[edit] Experience curve discontinuities

The experience curve effect can on occasion come to an abrupt stop.[citation needed] Graphically, the curve is truncated. Existing processes become obsolete and the firm must upgrade to remain competitive. The upgrade will mean the old experience curve will be replaced by a new one. This occurs when:

- Competitors introduce new products or processes that you must respond to

- Key suppliers have much bigger customers that determine the price of products and services, and that becomes the main cost driver for the product

- Technological change requires that you or your suppliers change processes

- The experience curve strategies must be re-evaluated because

- they are leading to price wars

- they are not producing a marketing mix that the market values

[edit] Strategic consequences of the effect

The BCG strategists examined the consequences of the experience effect for businesses. They concluded that because relatively low cost of operations is a very powerful strategic advantage, firms should capitalize on these learning and experience effects. [6] The reasoning is increased activity leads to increased learning, which leads to lower costs, which can lead to lower prices, which can lead to increased market share, which can lead to increased profitability and market dominance. According to BCG, the most effective business strategy was one of striving for market dominance in this way. This was particularly true when a firm had an early leadership in market share. It was claimed that if you cannot get enough market share to be competitive, you should get out of that business and concentrate your resources where you can take advantage of experience effects and gain dominant market share. The BCG strategists developed product portfolio techniques like the BCG Matrix (in part) to manage this strategy.

Today we recognize that there are other strategies that are just as effective as cost leadership so we need not limit ourselves to this one path.[citation needed] See for example Porter generic strategies which talks about product differentiation and focused market segmentation as two alternatives to cost leadership.

One consequence of the experience curve effect is that cost savings should be passed on as price decreases rather than kept as profit margin increases.[citation needed] The BCG strategists felt that maintaining a relatively high price, although very profitable in the short run, spelled disaster for the strategy in the long run. They felt that it encouraged competitors to enter the market, triggering a steep price decline and a competitive shakeout. If prices were reduced as unit costs fell (due to experience curve effects), then competitive entry would be discouraged and one's market share maintained. Using this strategy, you could always stay one step ahead of new or existing rivals.

[edit] Criticisms

Some authors claim that in most organizations it is impossible to quantify the effects. They claim that experience effects are so closely intertwined with economies of scale that it is impossible to separate the two.[citation needed] In theory we can say that economies of scale are those efficiencies that arise from an increased scale of production, and that experience effects are those efficiencies that arise from the learning and experience gained from repeated activities, but in practice the two mirror each other: growth of experience coincides with increased production. Economies of scale should be considered one of the reasons why experience effects exist. Likewise, experience effects are one of the reasons why economies of scale exist. This makes assigning a numerical value to either of them difficult.

Others claim that it is a mistake to see either learning curve effects or experience curve effects as a given. They stress that they are not a universal law or even a strong tendency in nature.[citation needed] In fact, they claim that costs, if not managed, will tend to rise.[citation needed] Any experience effects that have been achieved, result from a concerted effort by all those involved. They see the effect as an opportunity that management can create, rather than a general characteristic of organizations.

Another factor may be the attitude of the individuals involved. A strong negative attitude may negate any learning effect. Conversely a positive attitude may reinforce the effect.

[edit] See also

- Economies of scale

- Hermann Ebbinghaus

- Management

- Marketing strategies

- Porter generic strategies

- Strategic planning

- Gordon Moore's Law of affordable computing performance growth

- Mark Kryder's Law of magnetic disk storage growth

- Jakob Nielsen's Law of wired bandwidth growth

- Martin Cooper's Law of simultaneous wireless conversation capacity growth

[edit] References

- ^ Wright, T.P., Factors Affecting the Cost of Airplanes, Journal of Aeronautical Sciences, 3(4) (1936): 122-128.

- ^ Chase, Richard B. (2001). Operations management for competitive advantage, ninth edition. International edition: McGraw Hill/ Irwin. ISBN 0-07-118030-3.

- ^ Hax, Arnoldo C.; Majluf, Nicolas S. (October 1982). "Competitive cost dynamics: the experience curve". Interfaces 12: 50–61. doi:.

- ^ Grant, Robert M. (2004). Contemporary strategy analysis. U.S.,UK,Australia,Germany: Blackwell publishing. ISBN 1-4051-1999-3.

- ^ Learning Curve Calculator

- ^ Henderson, Bruce (1974, #149). "The Experience Curve Reviewed: V. Price Stability" ([PDF] Reprint). Perspectives (The Boston Consulting Group). http://www.bcg.com/publications/files/experiencecurveV.pdf. Retrieved on 2007-03-24.

[edit] Further reading

- Wright, Theodore Paul (February 1936), "Learning Curve", Journal of the Aeronautical Sciences

- Hirschmann, W. (Jan-Feb 1964), "Profit from the Learning Curve", Harvard Business Review

- Consulting, Boston (1972), Perspectives on Experience, Boston, Mass

- Abernathy, William; Wayne, Kenneth (Sept-Oct 1974), "Limits to the Learning Curve", Harvard Business Review

- Kiechel, Walter III (October 5, 1981), "The Decline of the Experience Curve", Fortune

- "Diagnosing the Experience Curve", Journal of Marketing 47 (Spring), 1983

- "Building Strategy on the Experience Curve", Harvard Business Review 42, March-April 1985

- The Learning Curve Deskbook: A Reference Guide to Theory, Calculations, and Applications, New York: Quorum Books, 1991

- Ostwald, Phillip F. (1992), Engineering Cost Estimating (3rd ed.), Prentice Hall, ISBN 0132766272

- Davies, Geoffrey F. (2004), Economia: New Economic Systems to Empower People and Support the Living World, ABC Books, ISBN 0733312985

- Le Morvan, Pierre; Stock, Barbara (2005), "Medical Learning Curves and the Kantian Ideal", The Journal of Medical Ethics 31