Breadboard

From Wikipedia, the free encyclopedia

| This article needs additional citations for verification. Please help improve this article by adding reliable references (ideally, using inline citations). Unsourced material may be challenged and removed. (August 2007) |

A breadboard (solderless breadboard, protoboard, plugboard) is a reusable sometimes[1] solderless device used to build a (generally temporary) prototype of an electronic circuit and for experimenting with circuit designs. This is in contrast to stripboard (veroboard) and similar prototyping printed circuit boards, which are used to build more permanent soldered prototypes or one-offs, and cannot easily be reused. A variety of electronic systems may be prototyped by using breadboards, from small analog and digital circuits to complete central processing units (CPUs).

The term breadboard is derived from an early form of point-to-point construction: in particular, the practice of constructing simple circuits (usually using valves/tubes) on a convenient wooden base, similar to a cutting board like the kind used for slicing bread with a knife. It can also be viewed as a bread with a large number of pores (holes for connection); like the bread most commonly used in America and Europe, a modern prototyping board is typically white or off-white.

Contents |

[edit] Evolution

Over time, breadboards have evolved greatly, with the term being used for all kinds of prototype electronic devices. For example, US Patent 3,145,483[2], filed in 1961 and granted in 1964, describes a wooden plate breadboard with mounted springs and other facilities. Six years later, US Patent 3,496,419[3], granted in 1970 after a 1967 filing, refers to a particular printed circuit board layout as a Printed Circuit Breadboard. Both examples also refer to and describe other types of breadboards as prior art. The classic, usually white, plastic pluggable breadboard, illustrated in this article, was designed by Ronald J Portugal of EI Instruments Inc. in 1971[4].

In the early days of radio, amateurs would nail bare copper wires or terminal strips to a wooden board (often literally a board for cutting bread) and solder electronic components to them.[5]. Sometimes a paper schematic diagram was first glued to the board as a guide to placing terminals, then components and wires were installed over their symbols on the schematic.

The integrated circuit for the Polaroid SX-70 camera was breadboarded before Texas Instruments fabricated the custom chip. It was rumored to have been built from discrete components on a 4 ft. x 8 ft. piece of plywood, and was fully functional.[citation needed]>

[edit] Typical specifications

A modern solderless breadboard consists of a perforated block of plastic with numerous tin plated phosphor bronze spring clips under the perforations. The spacing between the clips (lead pitch) is typically 0.1" (2.54 mm). Integrated circuits (ICs) in dual in-line packages (DIPs) can be inserted to straddle the centerline of the block. Interconnecting wires and the leads of discrete components (such as capacitors, resistors, inductors, etc.) can be inserted into the remaining free holes to complete the circuit. Where ICs are not used, discrete components and connecting wires may use any of the holes. Typically the spring clips are rated for 1 Ampere at 5 Volts and 0.333 Amperes at 15 Volts (5 Watts).

[edit] Bus and terminal strips

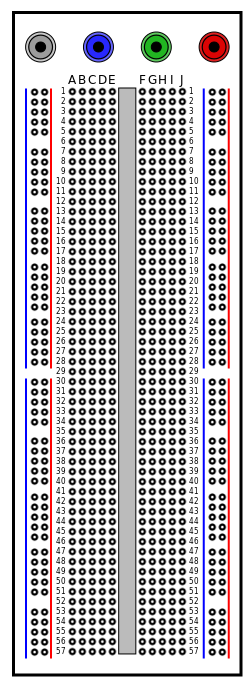

Solderless breadboards are available from several different manufacturers, but most share a similar layout. The layout of a typical solderless breadboard is made up from two types of areas, called strips. Strips consist of interconnected electrical terminals.

- terminal strips

- The main area, to hold most of the electronic components.

- In the middle of a terminal strip of a breadboard, one typically finds a notch running in parallel to the long side. The notch is to mark the centerline of the terminal strip and provides limited airflow (cooling) to DIP ICs straddling the centerline. The clips on the right and left of the notch are each connected in a radial way; typically five clips (i.e., beneath five holes) in a row on each side of the notch are electrically connected. The five clip columns on the left of the notch are often marked as A, B, C, D, and E, while the ones on the right are marked F, G, H, I and J. When a "skinny" Dual Inline Pin package (DIP) integrated circuit (such as a typical DIP-14 or DIP-16, which have a 0.3 inch separation between the pin rows) is plugged into a breadboard, the pins of one side of the chip are supposed to go into column E while the pins of the other side go into column F on the other side of the notch.

- bus strips

- To provide power to the electronic components.

- A bus strip usually contains two columns, one for ground, one for a supply voltage. But some breadboards only provide a single-column power distributions bus strip on each long side. Typically the column intended for a supply voltage is marked in red, while the column for ground is marked in blue or black. Some manufacturers connect all terminals in a column. Others just connect groups of e.g. 25 consecutive terminals in a column. The latter design provides a circuit designer with some more control over crosstalk (inductively coupled noise) on the power supply bus. Often the groups in a bus strip are indicated by gaps in the color marking.

- Bus strips typically run down one or both sides of a terminal strip or between terminal strips. On large breadboards additional bus strips can often be found on the top and bottom of terminal strips.

Some manufacturers provide separate bus and terminal strips. Others just provide breadboard blocks which contain both in one block. Often breadboard strips or blocks of one brand can be clipped together to make a larger breadboard.

In a more robust and slightly easier to handle variant, one or more breadboard strips are mounted on a sheet of metal. Typically, that backing sheet also holds a number of binding posts. These posts provide a clean way to connect an external power supply. Several images in this article show such solderless breadboards.

[edit] Diagram

A "full size" terminal breadboard strip typically consists of around 56 to 65 rows of connectors, each row containing the above mentioned two sets of connected clips (A to E and F to J). "Small size" strips typically come with around 30 rows.

Terminal Strip:

A B C D E F G H I J 1 o-o-o-o-o v o-o-o-o-o 2 o-o-o-o-o o-o-o-o-o 3 o-o-o-o-o o-o-o-o-o ~ ~ 61 o-o-o-o-o o-o-o-o-o 62 o-o-o-o-o o-o-o-o-o 63 o-o-o-o-o ^ o-o-o-o-o

Bus Strip:

V G o o | | o o | | o o | | o o | | o o | | | | o o | | o o | | o o | | o o | | o o | | | | ~ ~ o o | | o o

[edit] Jump wires

The jump wires for breadboarding can be obtained in ready-to-use jump wire sets or can be manually manufactured. The latter can become tedious work for larger circuits. Ready-to-use jump wires come in different qualities, some even with tiny plugs attached to the wire ends. Jump wire material for ready-made or home-made wires should usually be 22 AWG (0.33 mm²) solid copper, tin-plated wire - assuming no tiny plugs are to be attached to the wire ends. The wire ends should be stripped 3/16" to 5/16" (approx. 5 mm to 8 mm). Shorter stripped wires might result in bad contact with the board's spring clips (insulation being caught in the springs). Longer stripped wires increase the likelihood of short-circuits on the board. Needle-nose pliers and tweezers are helpful when inserting or removing wires, particularly on crowded boards.

Differently colored wires and color coding discipline are often adhered to for consistency. However, the number of available colors is typically far less than the number of signal types or paths. So typically a few wire colors get reserved for the supply voltages and ground (e.g. red, blue, black), some more for main signals, while the rest often get random colors. There are ready-to-use jump wire sets on the market where the color indicates the length of the wires; however, these sets do not allow applying a meaningful color coding schema.

[edit] Advanced breadboards

Some manufacturers provide high-end versions of solderless breadboards. These are typically high-quality breadboard modules mounted on some flat casing. The casing contains useful equipment for breadboarding, for example one or more power supplies, signal generators, serial interfaces, LED or LCD display modules, logic probes, etc.

Breadboard modules can also be found mounted on devices like microcontroller evaluation boards. They provide an easy way to add additional periphery circuits to the evaluation board.

[edit] Limitations

Due to large stray capacitance (from 2-25pF per contact point), high inductance of some connections and a relatively high and not very reproducible contact resistance, solderless breadboards are limited to operate at relatively low frequencies, usually less than 10 MHz, depending on the nature of the circuit. The relative high contact resistance can already be a problem for DC and very low frequency circuits. Solderless breadboards are further limited by their voltage and current ratings.

Breadboards usually cannot accommodate Surface mount technology devices (SMD) or non 0.1" (2.54 mm) grid spaced components, like for example those with 2 mm spacing. Further, they can not accommodate components with multiple rows of connectors, if these connectors don't match the DIL layout (impossible to provide correct electrical connectivity). Sometimes small PCB adapters (breakout adapters) can be used to fit the component on. Such adapters carry one or more of the non-fitting components and 0.1" (2.54 mm) connectors in DIL layout. The larger of the components are usually plugged into a socket, where the socket was soldered onto such an adapter. The smaller components (e.g. SMD resistors) are usually directly soldered onto such an adapter. The adapter is then plugged into the breadboard via the 0.1" connectors. However, the need to solder the component or socket onto the adapter contradicts the idea of using a solderless breadboard for prototyping in the first place.

Complex circuits can become unmanageable on a breadboard due to the large amount of wiring necessary.

[edit] Alternatives

Alternative methods to create prototypes are point-to-point construction, reminiscent of the original breadboards, wire wrap, wiring pencil, and boards like stripboard. Complicated systems, such as modern computers comprising millions of transistors, diodes and resistors, do not lend themselves to prototyping using breadboards, as sprawling designs on breadboards can be difficult to lay out and debug. Modern circuit designs are generally developed using a schematic capture and simulation system, and tested in software simulation before the first prototype circuits are built on a printed circuit board. Integrated circuit designs are a more extreme version of the same process: since producing prototype silicon is expensive, extensive software simulations are performed before fabricating the first prototypes. However, prototyping techniques are still used for some applications such as RF circuits, or where software models of components are inexact or incomplete.

[edit] See also

[edit] References

- ^ http://tangentsoft.net/elec/breadboard.html

- ^ U.S. Patent 3,145,483 Test Board for Electronic Circuits

- ^ U.S. Patent 3,496,419 Printed Circuit Breadboard

- ^ USD228,136 (1973-08-14) Ronald J. Portugal, breadboard for electronic components or the like.

- ^ Description of the term breadboard