Venturi effect

From Wikipedia, the free encyclopedia

| This article does not cite any references or sources. Please help improve this article by adding citations to reliable sources (ideally, using inline citations). Unsourced material may be challenged and removed. (December 2007) |

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section of pipe. The fluid velocity must increase through the constriction to satisfy the equation of continuity, while its pressure must decrease due to conservation of energy: the gain in kinetic energy is balanced by a drop in pressure or a pressure gradient force. An equation for the drop in pressure due to venturi effect may be derived from a combination of Bernoulli's principle and the equation of continuity.

The limiting case of the Venturi effect is when a fluid reaches the state of choked flow, where the fluid velocity approaches the local speed of sound. In choked flow the mass flow rate will not increase with a further decrease in the downstream pressure environment.

However, mass flow rate for a compressible fluid can increase with increased upstream pressure, which will increase the density of the fluid through the constriction (though the velocity will remain constant). This is the principle of operation of a convergent-divergent nozzle.

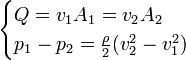

Referring to the diagram to the right, using Bernoulli's equation in the special case of incompressible flows (such as the flow of water or low speed flow of gas), the theoretical pressure drop (p1 − p2) at the constriction would be given by  .

.

The Venturi effect is named after Giovanni Battista Venturi, (1746–1822), an Italian physicist.

[edit] Experimental apparatus

- Venturi tubes

- The simplest apparatus, as shown in the photograph and diagram, is a tubular setup known as a Venturi tube or simply a venturi. Fluid flows through a length of pipe of varying diameter. To avoid undue drag, a venturi tube typically has an entry cone of 30 degrees and an exit cone of 5 degrees.

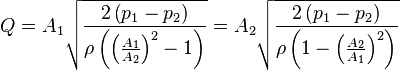

- A venturi can be used to measure the volumetric flow rate.

- Since

- Then

- A venturi can also be used to mix a liquid with a gas. If a pump forces the liquid through a tube connected to a system consisting of a venturi to increase the water speed (the diameter decreases), a short piece of tube with a small hole in it, and last a venturi that decreases speed (so the pipe gets wider again), the gas will be sucked in through the small hole because of changes in pressure. At the end of the system, a mixture of liquid and gas will appear. See aspirator and pressure head for a discussion of this type of siphon.

- Orifice plate

- Venturi tubes are more expensive to construct than a simple orifice plate which uses the same principle as a tubular scheme, but the orifice plate causes significantly more permanent energy loss.

Aortic insufficiency is a chronic heart condition that occurs when the aortic valve's initial large stroke volume is released and the Venturi effect draws the walls together, which obstructs blood flow, which leads to a Pulsus Bisferiens.

[edit] Practical uses

The Venturi effect may be observed or used in the following:

- The capillaries of the human circulatory system, where it indicates aortic regurgitation

- Large cities where wind is forced between buildings

- Cargo Eductors on Oil, Product and Chemical ship tankers

- Inspirators that mix air and flammable gas in grills, gas stoves, Bunsen burners and airbrushes

- Water aspirators that produce a partial vacuum using the kinetic energy from the faucet water pressure

- Steam siphons using the kinetic energy from the steam pressure to create a partial vacuum

- Atomizers that disperse perfume or spray paint (i.e. from a spray gun).

- Foam firefighting nozzles and extinguishers

- Carburetors that use the effect to suck gasoline into an engine's intake air stream

- Protein skimmers (filtration devices for saltwater aquaria)

- In automated pool cleaners that use pressure-side water flow to collect sediment and debris

- The barrel of the modern-day clarinet, which uses a reverse taper to speed the air down the tube, enabling better tone, response and intonation

- Compressed air operated industrial vacuum cleaners

- Venturi scrubbers used to clean flue gas emissions

- Injectors (also called ejectors) used to add chlorine gas to water treatment chlorination systems

- Sand blasters used to draw fine sand in and mix it with air

- Emptying bilge water from a moving boat through a small waste gate in the hull—the air pressure inside the moving boat is greater than the water sliding by beneath

- A scuba diving regulator to assist the flow of air once it starts flowing

- Modern vaporizers to optimize efficiency

- In Venturi masks used in medical oxygen therapy

- In recoilless rifles to decrease the recoil of firing

- Ventilators

A simple way to demonstrate the Venturi effect is to squeeze and release a flexible hose in which fluid is flowing: the partial vacuum produced in the constriction is sufficient to keep the hose collapsed.

Venturi tubes are also used to measure the speed of a fluid, by measuring pressure changes at different segments of the device. Placing a liquid in a U-shaped tube and connecting the ends of the tubes to both ends of a Venturi is all that is needed. When the fluid flows though the Venturi the pressure in the two ends of the tube will differ, forcing the liquid to the "low pressure" side. The amount of that move can be calibrated to the speed of the fluid flow.