Monocoque

From Wikipedia, the free encyclopedia

| This article needs additional citations for verification. Please help improve this article by adding reliable references (ideally, using inline citations). Unsourced material may be challenged and removed. (March 2009) |

Monocoque, from Greek for single (mono) and French for shell (coque), is a construction technique that supports structural load by using an object's external skin as opposed to using an internal frame or truss that is then covered with a non-load-bearing skin. Monocoque construction was first widely used in aircraft in the 1930s. Structural skin is another term for the same concept.

Unibody, or unitary construction, is a related construction technique for automobiles in which the body is integrated into a single unit with the chassis rather than having a separate body-on-frame. The welded "Unit Body" is the predominant automobile construction technology today.

Contents |

[edit] Aircraft

| This section does not cite any references or sources. Please help improve this article by adding citations to reliable sources (ideally, using inline citations). Unsourced material may be challenged and removed. (March 2009) |

Early aircraft were constructed using internal frames, typically of wood or steel tubing, which were then covered (or skinned) with madapolam or other fabric to provide the aerodynamic surfaces. This fabric would usually be tautened and stiffened using aircraft dope and was often required to brace the frame in tension but could provide no strength in compression; to resist buckling, these aircraft relied on the rigidity of the internal frame. Some early aircraft designers began to apply sheet metal or plywood to highly stressed parts of the internal frames; this skin did provide strength in shear and compression and could therefore be considered as early examples of monocoque elements but the aircraft still relied primarily on their internal frames.

In 1916 LFG introduced their Roland C.II using a fuselage made of moulded plywood, which provided both the external skin and the main load bearing structure. This made the plane immensely strong for its day, if a little heavy. Similar designs were also produced by Pfalz Flugzeugwerke, who had originally built the Roland under license.

By the late 1920s the price of aluminium, the principal ingredient of the aircraft alloy duralumin, had dropped considerably and duralumin was adopted extensively for internal framing members and later, the skin. It was realised that if the skin were made thick enough it could, theoretically, eliminate the need for any internal framing at all but this would be heavier than an internal frame. Thin sheet metal gauges could easily resist tension and shear loads but buckled under bending and compression. However, if curved, corrugated or rolled into pipe, sheet metal could be made strong against bending and compression loads as well. Stressed skins began to be combined with greatly reduced internal stiffening and came to be what is now known as semi-monocoque. For example, the Ford Trimotor retained an internal frame of U-shaped aluminium beams but relied on a thin skin of corrugated aluminium sheet to brace this. The corrugations allowed the Trimotor skin to take compression and bending loads, replacing most of the wing ribs and fuselage stringers and could be regarded as a stressed skin structure augmented by an internal frame or semi-monocoque structure. The skin itself had now become a significant structural element in its own right and it was to become even more important when airframes were required to take ever increasing loads.

In the 1930s huge increases in engine power, higher speeds, the need for fuel efficiency and, post World War II, operating altitudes that required aircraft cabins to be pressurised demanded streamlined airframes with stiff, strong, smooth skins; monocoque construction was ideal for this. Torsional (twisting) stiffness was essential to avoid aerolastic deformation under the rising aerodynamic loads. An outstanding early example is the Douglas DC-3. World War II was catalyst for aircraft development. At the beginning of the war monocoque construction was in its infancy and many aircraft still used mixed construction or internal frames; by the end of the war, all high-performance planes were monocoque or semi-monocoque.

Aerodynamic considerations of high performance aircraft began to demand the creation of three-dimensionally curved surfaces; a dome is a three-dimensionally curved surface. Happily, any sheet material acquires far more strength when curved in three dimensions as opposed to a simple two dimensional roll such as the Tri-motors corrugated skin. Although expensive to mould, three dimensional shells such as the de Havilland Mosquito moulded plywood fuselage provided immensely strong and light airframes.

Monocoque construction does not suit all situations. After World War II many lower-performance general aviation aircraft such as the Piper PA-20 Pacer still employed internal frames. Even external wire bracing is still retained for aircraft that have no internal volume such as hang gliders or ultralight, lightly stressed, slow aircraft for which a stressed skin would be too heavy, such as the human powered Gossamer Condor. This is because for very light loads skin stiffness becomes less important than airframe buckling and buckling can be resisted more weight-efficiently by concentrating the compression loads into a few internal struts kept in place by lightweight wire or fabric tension members. Bicycle wheels and tents use tension members in the same way to brace a few compression parts. Monocoque construction can still be more efficient, even in lightly loaded situations, where torsional resistance is the primary need.

An inadequate understanding of early, metal monocoque aircraft design resulted in catastrophic explosive decompressions of pressurised airframes. The two 1954 De Havilland Comet disasters resulted in a major investigation that solved the principal problems of monocoque aircraft construction. It was found that the Comet fuselage failures were caused by a combination of a poor understanding of how stresses are redistributed around openings in a stressed skin, such as the windows, and an inadequate theory of metal fatigue crack propagation. The lessons learnt from the Comet were incorporated directly into the design of the Boeing 707 and all subsequent airliners. The oval windows seen on all pressurised jet airliners are one legacy of this. Sound engineering and regular inspections for metal fatigue have made aircraft airframes very reliable. When a crack is found, all parts from that batch are traced and checked carefully or replaced. De Havilland had previously built thousands of wooden monocoque jet aircraft, the Vampires, copying their very successful Mosquito structure.

The use of composite materials in monocoque skins now allows strength, stiffness and flexibility to be controlled in different directions. Careful design of the direction of the grain of successive layers of materials used in the skin coupled with the use of carbon fibre can produce different mechanical properties in different directions while optimising for weight. Composite materials can be readily built up into complex three-dimensional shapes making them ideal for many aircraft components. They can also be built to be flexible in useful ways, for example, helicopter blades can be made longitudinally rigid but capable of being twisted transversally to adjust the cyclic pitch instead of being mounted on a pivot.

[edit] Automobiles

The first automotive application of the monocoque technique was 1923's Lancia Lambda. Chrysler and Citroën built the second monocoque vehicles, both in 1934, with the innovative Chrysler Airflow and the Traction Avant, respectively, and General Motors followed with the Opel Olympia in 1935. In 1936, Lincoln introduced the Zephyr, a monocoque design which was as strong as the Airflow yet much lighter.

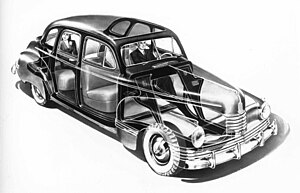

Nash Motors introduced this type of construction in 1941 with the new 600, generally credited with being the first popular mass-produced unibody construction automobile made in the United States. The all-welded steel with sturdy bridge-like girders that arched front to rear made for greater strength, safety, and longer life. Nash engineers claimed that about 500 pounds of excess weight was cut out (compared to body-on-frame automobiles) and the body's lower air drag helped it to achieve excellent gas mileage for its day. Prophetically, the company's 1942 news release text attached to the X-ray drawing describes how "... all auto bodies will be built ... as this some day..." The Alec Issigonis Morris Minor of 1948 featured a monocoque body. The Hudson Hornet, along with the rest of Hudson range, featured a monocoque body at the same time.

In the post-war period the technique became more widely used. Other automakers incorporated this type of construction and the terms unit body and unibody became more common in general use. The Ford Consul was the first Ford built in England using a unibody.

In 1960, a major breakthrough in unibody construction was reached in mass-produced Detroit vehicles with the Chevrolet Corvair, the most successful automobile of this type up to that time, with 1,786,243 cars being produced between 1960 and 1969[1][2]. Among its many other forward-thinking and breakthrough technologies for its day, the Corvair was built from uniform molds and relied on the shaping of the glass and doors for help with structural integrity[3]. Convertible versions needed special supports welded underneath to compensate for the missing shape on the top.

American Motors (AMC) continued its engineering heritage from Nash and Hudson with breakthroughs such as in 1963 of combining separate parts into single stampings. The Rambler Classic had "uniside" door surrounds from a single stamping of steel that reduced weight and assembly costs, as well as increasing structural rigidity and improving door fitment.

Spot welded unibody construction is now the dominant technique in automobiles, though some vehicles (particularly trucks) still use the older body-on-frame technique.

Some American automobiles, such as the 1967-81 Chevrolet Camaro and Pontiac Firebird, 1968-79 Chevrolet Nova and virtually all Chrysler Corporation automobiles from 1960 until the early 1980s, used a compromise design with a partial monocoque combined with a subframe carrying the front end and powertrain. The intention was to provide some of the rigidity and strength of a unibody while easing manufacture, although the results were mixed, in large part because the powertrain subframe contained the greatest single portion of the vehicle's overall mass, and thus movement of the subframe relative to the rest of the body could cause distortion and vibration. Subframes or partial subframes are still sometimes employed in otherwise monocoque construction, typically as a way of isolating the vibration and noise of powertrain or suspension components from the rest of the vehicle.

In automobiles, it is now common to see true monocoque frames, where the structural members around the window and door frames are built by folding the skin material several times. In these situations the main concerns are spreading the load evenly, having no holes for corrosion to start, and reducing the overall workload. Compared to older techniques, in which a body is bolted to a frame, monocoque cars are less expensive, lighter, more rigid, and can be more protective of occupants in a crash when appropriately designed.

Monocoque design is so sophisticated that windshield and rear window glass now often make an important contribution to the designed structural strength of automobiles. Unfortunately, when a vehicle with a unibody design is involved in a serious accident, it may be more difficult to repair than a vehicle with a full frame. Rust is also more of a problem, since the structural metal is part of the load bearing structure making it more vulnerable, and must be repaired by cutting-out and welding rather than by simply bolting on new parts (as would be the case for a separate chassis). Older cars with separate chassis can still pass vehicle inspection tests (such as the British MoT) with quite advanced rust in the sills (rocker panels) and pillars, whereas in more modern cars these parts are structural and would lead to a test failure. In the United States, in the majority of the states which require safety inspections, vehicles will not pass inspection if rust has perforated components such as rocker panels, floor pans, or pillars - regardless of the type of body construction.[citation needed]

Some parts of the skin like the grill, the bumpers, the fenders, front wing and rear diffuser are so far away from any load paths that they only hold themselves. The doors and the hood can only transfer a limited amount of load across their gaskets, hinges, and bolts in normal driving situations. The rear door is both far away from any load paths and separated by a gasket. The rear door is a mini-monocoque made of the glass window and the metal frame.[citation needed]

Monocoque designs are favored amongst high-performance cars and racing cars today for their overall structural integrity and the fact that one can design a monocoque out of lightweight materials such as carbon fiber and expect the resulting vehicle to be light, stiff, and stable at high speeds and in tight corners. These types of particularly advanced monocoques can even be molded to create diffusers and ground effects which generate huge amounts of downforce.[citation needed]

[edit] Architecture

| This section requires expansion. |

Architects occasionally take advantage of the increasing sophistication of monocoque technology in their building projects. Using monocoque technology in buildings allows for interior spaces without columns and load-bearing walls; this creates more spatial and programmatic openness inside.

Notable examples are reinforced concrete shells.

Many 1950s and 1960s UK underground protected nuclear bunkers were constructed as reinforced concrete monocoque structures for their inherent strength, robustness and protective factors. Often described as "underground submarines" in that, if they were dug up and placed in water, they would have floated and stayed waterproof.

Future Systems, a firm based in the United Kingdom, designed the Media Centre at Lord's Cricket Ground in 1999. It is a monocoque structure constructed in aluminium. It was manufactured by Pendennis Shipyard in Falmouth, drawing on the company's boatbuilding experience.

Buckminster Fuller used the monocoque technique in the construction of the Wichita House (based on the Dymaxion design).[4]

Neil Denari is another architect whose work to date has exhibited a monocoque-like approach to the cladding and external appearances of otherwise conventionally-structured projects.

An igloo (and any uniform dome) is of full monocoque design, while a geodesic dome is a hybrid design, combining monocoque and frame elements. Quonset huts, hogans, and yurts are more examples.

Structural Insulated Panels, or SIPs, are a type of preinsulated modular wall system. Formerly called "stressed skin panels", they are monocoques in and of themselves. Fastened together properly, they can yield a monocoque housing structure.

[edit] Boats and ships

| This section does not cite any references or sources. Please help improve this article by adding citations to reliable sources (ideally, using inline citations). Unsourced material may be challenged and removed. (March 2009) |

Small boats, like kayaks and canoes, are typically of monocoque construction, while large ships tend to have frames. Mid-sized ships and boats (including submarines) may be of either design, or a hybrid of the two.

[edit] Bicycles

| This section does not cite any references or sources. Please help improve this article by adding citations to reliable sources (ideally, using inline citations). Unsourced material may be challenged and removed. (March 2009) |

Primarily due to the widespread use of carbon fibre in bicycle frame construction, monocoque framesets are becoming increasingly common. The American company Kestrel USA pioneered the use of carbon fibre monocoques in bike frame manufacture in the 1980s, and since then the technique has become increasingly widely used due to its stiffness and light weight. Items such as seatposts and other components are now employing the same technique.

[edit] Motorcycles

| This section does not cite any references or sources. Please help improve this article by adding citations to reliable sources (ideally, using inline citations). Unsourced material may be challenged and removed. (March 2009) |

A Grand Prix motorcycle racing monocoque motorcycle was developed in 1967 by Ossa, a Spanish motorcycle brand. Honda also experimented with a monocoque motorcycle in 1979 with its NR500. Monocoque construction has begun to see application in motorcycle chassis production, for example, the 2005 model year Kawasaki Ninja ZX-14. Road racing sidecars in the Formula 1 class have used monocoque chassis since the mid 1970s, such as those manufactured by LCR.

[edit] Scooters

| This section does not cite any references or sources. Please help improve this article by adding citations to reliable sources (ideally, using inline citations). Unsourced material may be challenged and removed. (March 2009) |

Scooters produced by Vespa and other companies are made from a pressed steel monocoque frame. This innovative design lead to the light weight and high fuel efficiency of scooters, and contributed to their popularity.

[edit] Rockets

| This section does not cite any references or sources. Please help improve this article by adding citations to reliable sources (ideally, using inline citations). Unsourced material may be challenged and removed. (March 2009) |

The Falcon I rocket recently developed by SpaceX uses a graduated monocoque, flight pressure-stabilized design for its first stage. This pressure-stabilized design was also used by the Atlas II rocket.

[edit] See also

- Backbone chassis

- Frame (vehicle)

- Body Frame Integral

- Body-on-frame

- Coachbuilder

- Monokote a plastic model aircraft coating.

- Strut Bar

- Spaceframe

- Superleggera

- Thin-shell structure

[edit] References

- ^ [1] Corvair Unibody Manufacture Reference

- ^ [2] Corvair Production Totals

- ^ [3] Chevrolet Corvair: Photo History, by Monty Montgomery, ISBN-13: 9781583881187, (2004)

- ^ Harvard University (undated). "Buckminster Fuller - Wichita House". http://www.gsd.harvard.edu/studios/s97/burns/p_fuller.html. Retrieved on 2009-02-12.

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||